Unveiling the three core tests: withstand voltage, combustion, and tensile testing.

2025-09-09

What tests do cables undergo before leaving the factory? Unveiling the three core tests: withstand voltage, combustion, and tensile testing.

Every roll of cable leaving the factory undergoes a series of rigorous tests. These tests are not mere formalities; they represent a solemn commitment to safety and quality. Wires and cables are the "blood vessels" of power transmission. Failure during operation can cause equipment downtime at best, or even serious accidents like fire and electric shock. Therefore, before leaving the production line, cables must pass multiple key performance verifications. Withstand voltage testing, combustion testing, and tensile testing are three essential core tests. These tests comprehensively guarantee cable reliability from the perspectives of electrical safety, fire resistance, and mechanical strength.

1. Withstand voltage testing: Verifying the "lifeline" of insulation

The insulation layer of a cable is a critical barrier against leakage, short circuits, and electric shock. The purpose of the withstand voltage test (also known as the power frequency withstand voltage test) is to verify the insulation material's ability to withstand high voltages, ensuring it will not break down during long-term operation.

The test process is as follows:

A specified length of cable is immersed in water (the conductor is connected to the high voltage, and the water serves as the ground). An AC voltage significantly higher than the rated voltage (for example, 0.6/1kV cables must withstand 3.5kV) is then applied for 5 minutes. If the cable does not experience breakdown or flashover during this period, it is considered qualified.

This test simulates the extreme operating conditions that cables may experience under abnormal conditions such as lightning strikes and switching overvoltages. The withstand voltage test effectively detects defects such as bubbles, impurities, and uneven thickness in the insulation layer, eliminating the risk of defective cables leaving the factory.

II. Flame Test: Testing the Cable's Fire Resistance

Fire is one of the most hazardous scenarios for cables. Ordinary cables in flames not only fuel the fire but also release large amounts of toxic smoke, hindering escape. Therefore, modern cables must possess certain flame-retardant or fire-resistant properties, which are verified through standardized flame tests.

Common flame tests include:

-Single-cable vertical flame test (IEC 60332-1): A cable is fixed vertically and subjected to a flame for 60 seconds before being removed. A qualified cable should self-extinguish, with the charred portion not exceeding the specified height. This test is used to evaluate the basic performance of standard flame-retardant cables.

-Bundled flame test (IEC 60332-3): Multiple cables are arranged in a bundle and subjected to a larger flame for 20 minutes (Type A) or 40 minutes (Type C). Cables that pass this test demonstrate effective flame resistance even in densely packed environments and are suitable for use in high-risk areas such as cable tunnels and shafts.

-Fire resistance test (IEC 60331): The cable is subjected to a flame (750°C to 950°C) for 90 minutes while simultaneously applying rated voltage and mechanical vibration. After the test, the cable remains energized, demonstrating its ability to maintain critical circuit operation during a fire.

In addition, low-smoke, zero-halogen (LSZH) cables are also subject to smoke density testing (IEC 61034) and halogen acid gas emission testing (IEC 60754) to ensure low smoke and low toxicity during combustion.

III. Tensile Test: Verifying the Mechanical Strength of Conductors and Sheaths

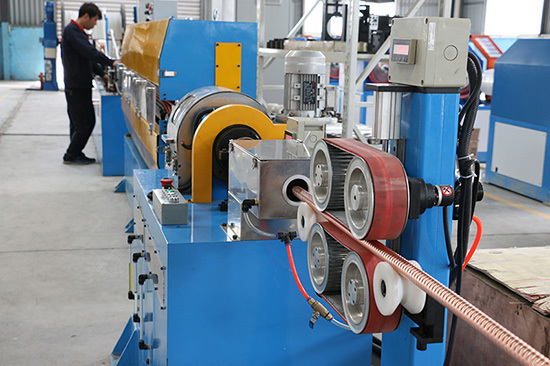

During installation and use, cables are often subjected to mechanical stresses such as tension, bending, and compression. Tensile testing (also known as mechanical performance testing) assesses the tensile strength of the cable as a whole and its materials to prevent breakage or damage caused by external forces.

This test primarily involves two aspects:

1. Conductor Tensile Test: A section of copper or aluminum conductor is stretched on a tensile testing machine to measure its tensile strength and elongation at break. For example, a standard oxygen-free copper conductor should have a tensile strength of at least 200 MPa and an elongation of at least 20%. Materials that are too brittle or too soft do not meet these requirements.

2. Sheath and Insulation Mechanical Performance Testing: Samples are taken from the cable and made into dumbbell-shaped specimens. The tensile strength and elongation at break are tested before and after aging (e.g., 80°C for 168 hours). This test reflects the material's durability in long-term operation and helps prevent sheath cracking and insulation embrittlement.

In addition, bending and impact tests are conducted to simulate the actual stresses experienced by the cable during conduit and cable tray installation.

--

Conclusion: Every test is a responsibility for life.

The withstand voltage test ensures electrical safety, the combustion test strengthens the fire barrier, and the tensile test ensures mechanical reliability. These three core tests are just a portion of the numerous tests performed before the cable leaves the factory. In addition, conductor resistance testing, structural dimensional inspection, and thermal elongation testing complete the comprehensive quality control system.

Every reel of cable that passes this test carries a commitment to user safety. It is this seemingly boring laboratory data that provides a barrier of peace of mind for our daily electrical use. Choosing a cable is not just about selecting a material; it is about choosing a reliable guarantee that has been rigorously tested.

Relevant news

Quick Quote

* Note: Please be sure to fill in the information accurately and keep the communication open. We will get in touch with you as soon as possible

Copyright © 2023 Shandong Zhongmai Cable Co., Ltd