In-depth understanding of the definition and classification differences of PVC insulated cables

2025-08-21

PVC insulated cable (PVC) is a type of wire and cable primarily insulated with polyvinyl chloride (PVC). It is widely used in power, lighting, control, and signal transmission systems with rated voltages of 450/750V and below. Its conductors are typically annealed copper or aluminum wire, with an extruded PVC insulation layer. With advantages such as low cost, good processability, and strong flame retardancy, it is one of the most common cable types used in building and industrial electrical systems.

I. Definition

PVC insulated cable refers to a metal conductor coated with a layer of PVC insulation via an extrusion process. Various types and specifications are available, depending on whether or not a sheath is present, the conductor structure, and the intended use. These cables comply with the following standards: China National Standard GB/T 5023 and International Electrotechnical Commission Standard IEC 60227. They are suitable for fixed wiring, equipment connections, and indoor installations.

II. Classification

Based on their application and structural characteristics, PVC insulated cables can be divided into the following categories:

- BV: Single-core copper-core PVC insulated cable with a single-strand rigid conductor. Suitable for fixed installations, such as wall conduit routing, it offers excellent electrical performance and mechanical strength, but suffers from poor flexibility.

- BVR: Multi-stranded soft copper conductors are more flexible than BV, making them easier to bend and run through conduits. They are commonly used for wiring inside distribution boxes or in applications requiring a certain degree of mobility.

- RVV: Multi-core PVC-insulated and PVC-sheathed flexible cable. It consists of multiple RV cores covered with a PVC sheath. It offers a certain degree of mechanical protection and is suitable for mobile or semi-fixed connections in electrical equipment, small power plants, temporary power supplies, and other applications.

- RVVP: RVV is based on RVV and features an additional copper wire braided shield, providing improved electromagnetic interference resistance. It is suitable for applications requiring high signal stability, such as instrument signal transmission, monitoring systems, and communications equipment.

- BVVB: Flat PVC-sheathed cable, with two or more insulated cores extruded and wrapped side by side into a flat shape for concealed installation and conduit routing. Commonly used for household lighting and socket circuits.

- NH-BV: Fire-resistant PVC-insulated cable, with fire-resistant mica tape added between the conductor and the insulation. This cable can maintain circuit power for a certain period (usually 90 minutes) under fire conditions. It is used for critical equipment such as emergency lighting, fire pumps, and smoke exhaust systems.

- ZR (such as ZR-BV and ZR-RVV): Flame-retardant cable, made of flame-retardant PVC, slows combustion and prevents fire spread under fire conditions. It is suitable for environments with high fire protection requirements, such as high-rise buildings and crowded places.

III. Usage Characteristics and Differences

The various types of PVC-insulated cables have significant differences in their usage characteristics. BV cable has a simple structure and low cost, making it suitable for long-term fixed installations, but it is not easy to bend. BVR, with its multi-strand twisted conductor, is more flexible and suitable for frequent bending or complex conduit routing. RVV cables feature a sheath, offering enhanced tensile strength and moisture resistance, making them suitable for equipment power connections. RVVP cables, with their shielding layer, effectively suppress external electromagnetic interference and ensure signal transmission quality. Fire-resistant NH-BV cables, while identical to standard BV cables during normal operation, maintain circuit integrity in high-temperature flames, making them a crucial component of fire safety systems. Flame-retardant cables, with optimized material formulations, release less heat during combustion and exhibit strong self-extinguishing properties.

The long-term operating temperature for all PVC-insulated cables is generally 70°C, with short-term overloads not exceeding 90°C. The installation temperature should not drop below -15°C, as this can cause the PVC material to become brittle and crack. Furthermore, PVC releases toxic gases such as hydrogen chloride and dense smoke when burned. Therefore, low-smoke, halogen-free (WDZ) alternatives should be considered in confined spaces or crowded areas.

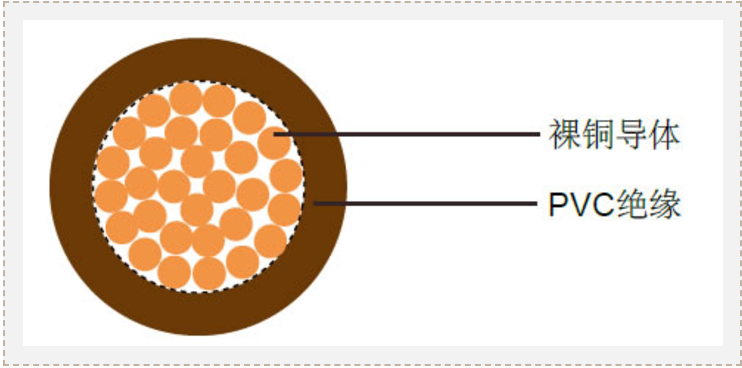

IV. Structure and Dimensions

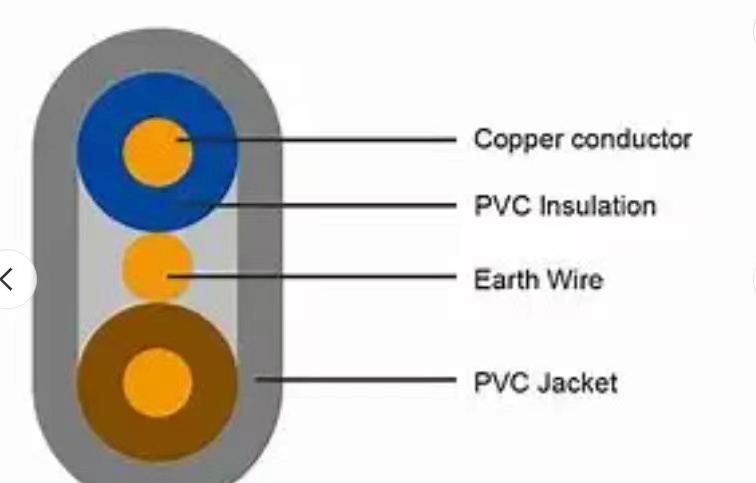

Take the common BV-1.5mm² cable as an example. Its structure, from the inside out, is as follows: a round annealed copper conductor with a diameter of approximately 1.38mm, surrounded by an extruded PVC insulation layer approximately 0.8mm thick, for an overall outer diameter of approximately 3.2mm. Different cross-section specifications (such as 1.0, 1.5, 2.5, 4, 6, and 10mm²) correspond to different conductor diameters and insulation thicknesses, all of which must comply with the tolerances specified in GB/T 5023. Multi-core cables, such as RVV, consist of multiple insulated cores twisted together and then encased in an outer sheath, resulting in a more complex structure and a correspondingly larger outer diameter.

V. Application Scenarios

PVC insulated cables are widely used in various applications:

In residential buildings, BV and BVR cables are commonly used for fixed wiring between indoor lighting, sockets, and distribution boxes. BVVB flat cables are widely used for pre-buried wiring in residential walls due to their ease of conduit routing and concealed installation. In industrial equipment, RVV cables are used for power connections to motors and control cabinets; RVVP cables are used for signal transmission in weak current systems such as PLCs, sensors, and instruments, ensuring interference resistance. In fire protection systems, NH-BV cables must be used for power supply lines to critical loads such as emergency lighting, fire alarm controllers, and fire fans. For temporary power applications or construction sites, BVR and RVV cables are widely used due to their flexible installation and ease of movement. In environments with high humidity or mechanical damage risk, sheathed BVV or RVV cables should be selected for enhanced protection.

VI. Risk Mitigation Measures

When using PVC insulated cables, be aware of the following risks and mitigation strategies:

First, prevent overload. PVC insulation has a limited temperature resistance rating. Prolonged overload operation can cause insulation aging, softening, or even breakdown. Conductor cross-sections should be appropriately selected based on the load current, and circuit breakers or fuses should be used for protection to ensure timely power interruption in the event of an emergency.

Second, prevent mechanical damage. PVC is a hard material that is brittle at low temperatures and can crack when squeezed, bent, or impacted. During installation, cables should be protected through conduits to avoid contact with sharp objects, especially during concrete pouring or renovation.

Third, prevent fire risks. Common PVC cables produce toxic fumes and corrosive gases when burned, hindering escape and equipment safety. Flame-retardant (ZR) or low-smoke, halogen-free (WDZ) cables should be preferred in high-rise buildings, subways, hospitals, and other important locations to reduce fire hazards.

Fourth, prevent environmental aging. Long-term exposure to sunlight or high-temperature, high-humidity environments can accelerate aging, discoloration, and cracking of PVC cables. Cables should be protected from direct sunlight. For outdoor use, armored or UV-resistant sheathed cables are recommended.

Fifth, address electromagnetic interference. Unshielded cables may affect signal transmission quality in strong electromagnetic fields. For communications, monitoring, and automation control systems, shielded cables such as RVVP should be used, and the shield should be reliably grounded at one or both ends.

Sixth, eliminate counterfeit and substandard products. Issues such as insufficient conductor cross-section, insufficient insulation thickness, and inferior PVC materials are common in the market. When purchasing, choose products from reputable manufacturers, check for the CCC mandatory certification mark, request factory inspection reports, and conduct random sampling tests when necessary.

VII. Summary

PVC insulated cables remain the mainstream choice for low-voltage power distribution systems due to their low price, easy installation, and stable electrical performance. However, in actual applications, they must be appropriately selected based on the specific application, environmental conditions, and safety level. Installation specifications must be strictly adhered to, and appropriate protective measures must be implemented. For special applications such as fire protection, signal transmission, and humid or high-temperature environments, fire-resistant, shielded, flame-retardant, or protective cables should be selected. Furthermore, strengthening material quality control and preventing substandard products from entering the project site is crucial to ensuring the safe, reliable, and long-term operation of the power system.

Relevant news

Quick Quote

* Note: Please be sure to fill in the information accurately and keep the communication open. We will get in touch with you as soon as possible

Copyright © 2023 Shandong Zhongmai Cable Co., Ltd