Advantages of high-performance irradiation cables

2023-03-17

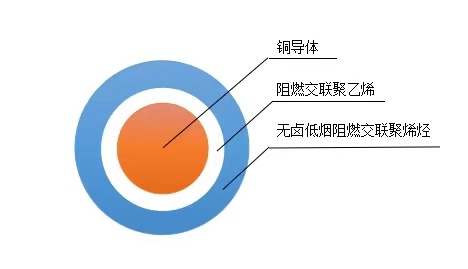

High performance and long lifespan wires and cables adopt the cable process and technology used in nuclear power plants, double-layer insulation structure, and irradiation cross-linking process (both insulation and sheath are subjected to irradiation cross-linking), ensuring the mechanical and physical properties, electrical properties, low smoke and halogen-free flame retardant performance, and extending the service life of the cable. The characteristics of high performance and long lifespan.

The product has characteristics such as halogen-free, low smoke, flame retardant, fire-resistant, non-toxic, long service life, high operating temperature, and high current carrying capacity.

The service life of the product at 70 ℃ shall not be less than 70 years.

Purpose: This product is suitable for distribution networks or industrial installations with a rated voltage of 0.6/1kV or below. It can be used in all densely populated public places such as shopping malls, theaters, stations, airports, etc.

Working temperature: The long-term allowable operating temperature of cable conductors is 90 ℃, 105 ℃, and 125 ℃; The working temperature during short circuit shall not exceed 250 ℃.

Laying temperature: It is not recommended to lay cables when the ambient temperature is below 0 ℃, otherwise heating measures should be taken.

Bending radius: minimum allowable bending radius of the cable: single core cable: 20D without armor, 15D with armor; Multi core cable: 15D without armor, 12D with armor.

★ Anti aging

Aging of electrical wires is one of the main causes of fires, After the aging of the wire, the mechanical strength of the insulation deteriorates, and even cracks when slightly touched and rubbed, losing the insulation protection function. When the live wire and the zero wire partially touch, sparks are generated, which can seriously cause fire accidents.

★ High temperature resistance

After being bombarded by high-energy electron irradiation, the molecular chains of this insulating material are broken, and after reassembly, the polymer changes from a linear to a three-dimensional network structure, with a stable structure. Plastic is not easy to melt at high temperatures, thus achieving high temperature resistance of wires. Through high current short circuit simulation experiments, it can be proven that normal operation can be maintained for a period of time under a current carrying capacity of more than 5 times, while ordinary wires will melt, smoke, and even catch fire. High temperature resistance is the main reason why long life wires can be safely used.

★ Long lifespan

In the early 1990s, China changed the wiring used in buildings from open wire laying to concealed conduit wiring, as the service life of ordinary wires is only about 20 years. Due to the hassle of replacing wires, this practice has buried safety hazards in a large number of our buildings. According to statistics, many building fires are caused by aging electrical wires.

The designed lifespan of double-layer insulated irradiation wires is over 70 years, which can achieve the same lifespan as buildings without the need for secondary wire replacement, reducing social costs while ensuring safety.

★ Waterproof insulation

There are reasons why long-life wires and cables adopt double-layer insulation. From the perspective of insulation performance, the volume resistivity of low smoke halogen-free insulation material is only 10 12 Ω. M, while the volume resistivity of irradiated cross-linked polyethylene is 1016 Ω. M, which is far higher than that of low smoke halogen-free material. At the same time, the material is non-polar molecule, compact in structure, difficult to penetrate water molecules, and has good waterproof performance. The main reason why irradiated cross-linked polyethylene is used as the inner layer of long-life wires is to provide waterproof, insulation and anti-aging properties of wires.

★ Environmentally friendly and non-toxic

The biggest harm of ordinary electric wires in a fire is the thick smoke emitted, which immediately fills the entire space of the enclosed area, causing poor visibility, and people inside cannot find a way to escape. It can also cause secondary disasters such as stampede accidents. So the fire accidents caused by wires and cables have a very large number of casualties.

Unlike ordinary wires, all materials used in long-life wires and cables are environmentally friendly. Except for metals such as cadmium and lead, they are low smoke, halogen-free, and non-toxic when burned. Meet the EU's requirements for environmental protection. During the short-circuit destructive test, it was clearly observed that a large amount of yellow and white smoke emitted from ordinary wires affected the line of sight, and at the same time, droplets were generated. And the Zhengsheng wire will not release gas or produce droplets.

From the test report, it can be seen that the toxicity index of long-life wires and cables after combustion is not greater than 5, and the release of halogen acid gas is not more than 5mg/.

Quick Quote

* Note: Please be sure to fill in the information accurately and keep the communication open. We will get in touch with you as soon as possible

Copyright © 2023 Shandong Zhongmai Cable Co., Ltd