Mineral insulated cables: Provide you with more secure power transmission

2024-11-14

Mineral insulated cables: Provide you with more secure power transmission

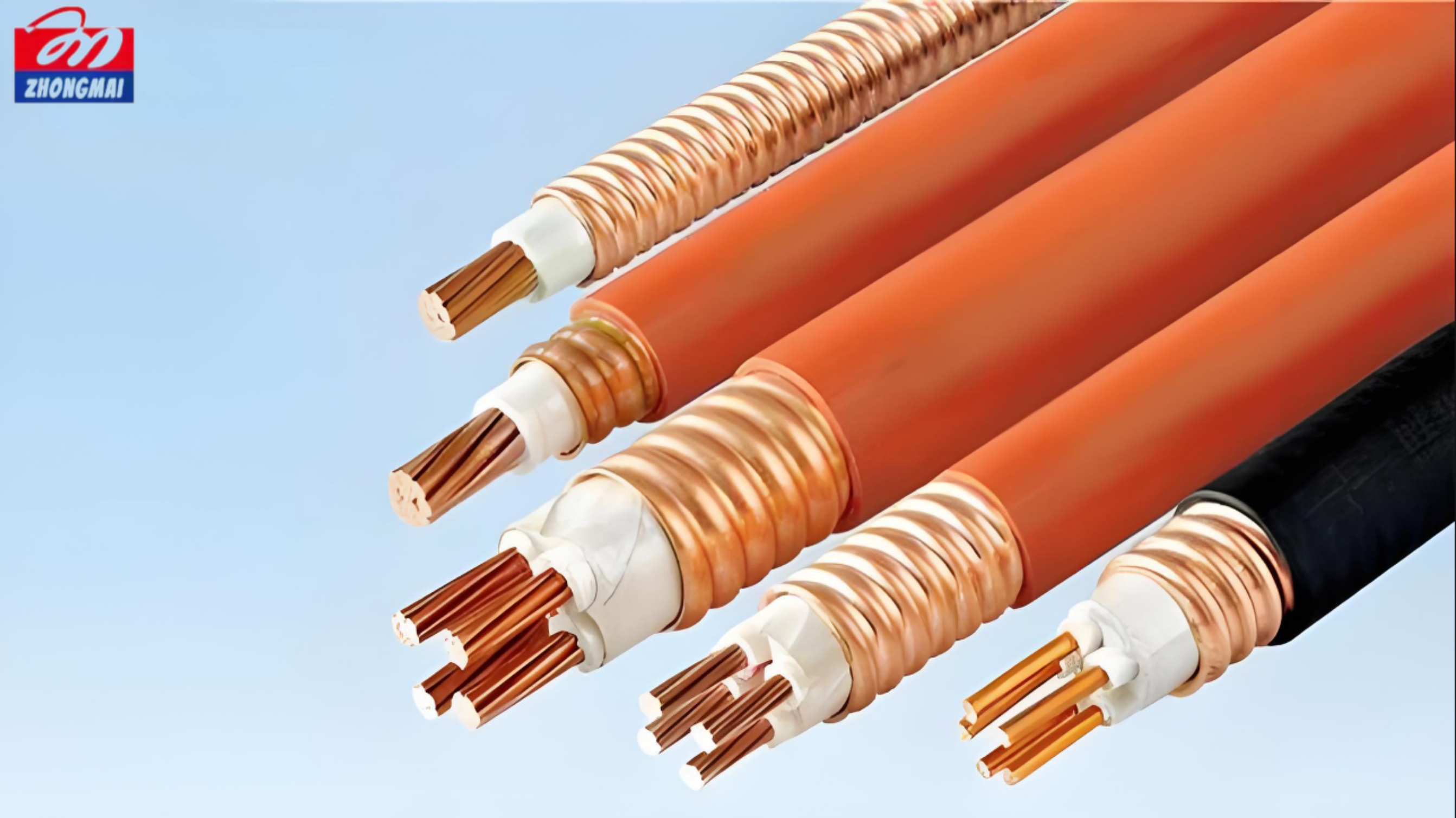

MineralInsulatedCable (MIC) is a special type of cable, which consists of a metal conductor and a mineral insulation material tightly wrapped around the outer layer of the conductor, and the outermost layer is covered with a metal sheath. This structure makes mineral insulated cables have extremely high heat resistance, fire resistance and mechanical strength, which is suitable for power transmission and signal transmission in a variety of harsh environments.

Definition and classification

Definition: Mineral insulated cable is a kind of cable with inorganic mineral materials as an insulating layer and metal tubes as a protective layer. The common mineral insulation material is magnesium oxide (MgO), the metal conductor is usually copper or copper alloy, and the external metal jacket is also copper or copper alloy.

Categories:

According to the number of conductors: single-core cable, two-core cable or multi-core cable.

Divided by use: power cable, control cable, signal cable, etc.

According to the structural characteristics: ordinary type, flexible type, refractory type, etc.

Use occasion:

Because of its excellent performance, mineral insulated cables are particularly suitable for the following occasions:

High temperature environment: near high temperature equipment in metallurgical, chemical and other industries.

Places requiring high reliability: such as nuclear power plants, subways, tunnels, high-rise buildings, etc.

Flammable and explosive environment: such as oil, gas and other industry facilities.

Where there are special requirements for cables: such as corrosion resistance, rat bite resistance, etc.

Advantage:

1. High temperature resistance: Mineral insulated cables can work in an environment of up to 250°C for a long time, and can withstand temperatures above 950°C for a short time.

2. Good fire performance: even in the flame, the cable can maintain integrity, will not produce harmful gases, to ensure the safety of personnel.

3. High mechanical strength: due to the use of metal sheath, the cable has good tensile, compressive and bending resistance.

4. Long service life: Due to the use of inorganic materials, not easy to age, so the service life is long.

5. Strong waterproof performance: closed metal sheath can effectively prevent water intrusion, suitable for humid environment.

6. Corrosion resistance: It has good resistance to some chemical substances and is suitable for corrosive environments.

7. Good electromagnetic compatibility: metal sheath can shield external electromagnetic interference to ensure the quality of signal transmission.

To sum up, mineral insulated cables are widely used in many fields because of their unique properties, especially in situations with high safety and reliability requirements.

Mineral insulated cable (MICC or MI cable) is a special type of cable that is known for its excellent fire resistance. Such cables are usually composed of copper conductors, magnesium oxide insulation and copper sheathing, sometimes with additional protective covers to enhance their physical properties.

Main features:

1. Fire resistance: Because the cable is composed of inorganic materials, it is not easy to burn, and can maintain the integrity of the circuit under fire conditions, thus ensuring the continuous operation of the critical system.

2. High operating temperature: Mineral insulated cables can withstand continuous operating temperatures of up to 250°C and, in extreme cases, temperatures close to the melting point of copper (1083°C).

3. Long life: Due to the use of inorganic materials, these cables have high stability and long life.

4. Explosion-proof: the closed structure inside the cable can prevent the transmission of gas or flame through the cable.

5. Small outer diameter: Compared with other types of cables with the same carrying capacity, the diameter of mineral insulated cables is smaller.

6. Waterproof: Even if completely immersed in water, mineral insulated cables can continue to work.

7. High mechanical strength: the cable has good resistance to mechanical damage.

8. Large carrying capacity: the carrying capacity of mineral insulated cables is higher than that of other cables of the same size.

9. High short-circuit fault rating: at the same temperature, the short-circuit capacity of mineral insulated cables is larger.

10. Grounding performance: Copper sheath can be used as an effective grounding path.

11. Corrosion resistance: Copper sheath has good corrosion resistance, suitable for use in a variety of environments.

Application field:

Because of its unique performance, mineral insulated cables are widely used in applications requiring high reliability and safety, such as high-rise buildings, petrochemical facilities, airports, subways, ships, offshore platforms, aerospace, iron and steel metallurgy and other industries. Especially in the fire, emergency lighting, emergency broadcast, elevator, fire alarm, computer room control lines and other systems with strict requirements for fire resistance.

Categories:

Rigid mineral insulated cable: The structure is hard, difficult to bend, suitable for fixed installation.

Flexible mineral insulated cable: with good flexibility, easy to install, suitable for bending or moving occasions.

Standards and Certifications:

Mineral insulated cables must comply with relevant international and national standards, such as BS6387, GB/T19216.21, etc., to ensure their performance and reliability under specific conditions. For example, the BS6387 standard defines fire resistance test methods for cables to maintain line integrity under flame conditions, including C (simple combustion), W (spray), Z (impact) and other test items.

In short, mineral insulated cables play an important role in many key applications due to their excellent fire resistance, high operating temperature, long life and good mechanical properties.

If you have any needs, please contact:

Tel:+86-13515398886

E-mail:sunny@electriccable.cn

sandy@electriccable.cn

cassie@electriccable.cn

Quick Quote

* Note: Please be sure to fill in the information accurately and keep the communication open. We will get in touch with you as soon as possible

Copyright © 2023 Shandong Zhongmai Cable Co., Ltd